1000KN Steel Rebar Universal Tensile Testing Machine

- Tlhaloso ea Sehlahisoa

Electro-Hydraulic Servo /Microcomputer Universal Testing Machine

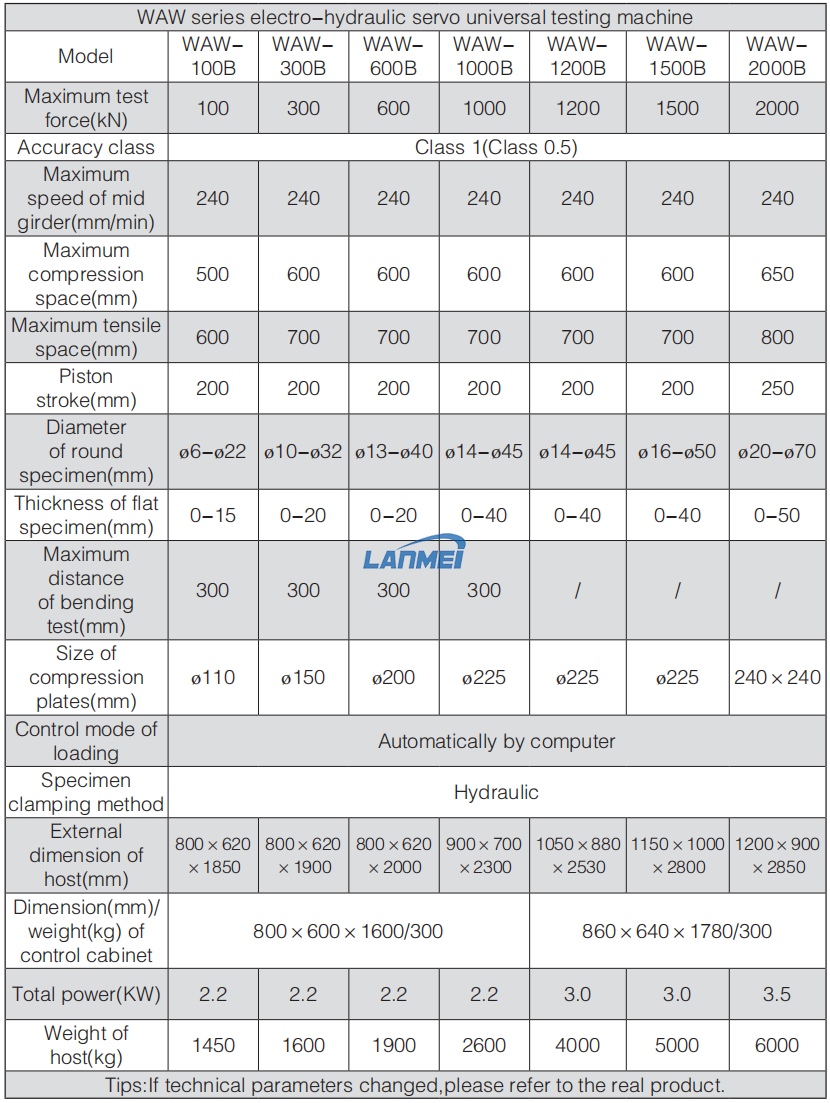

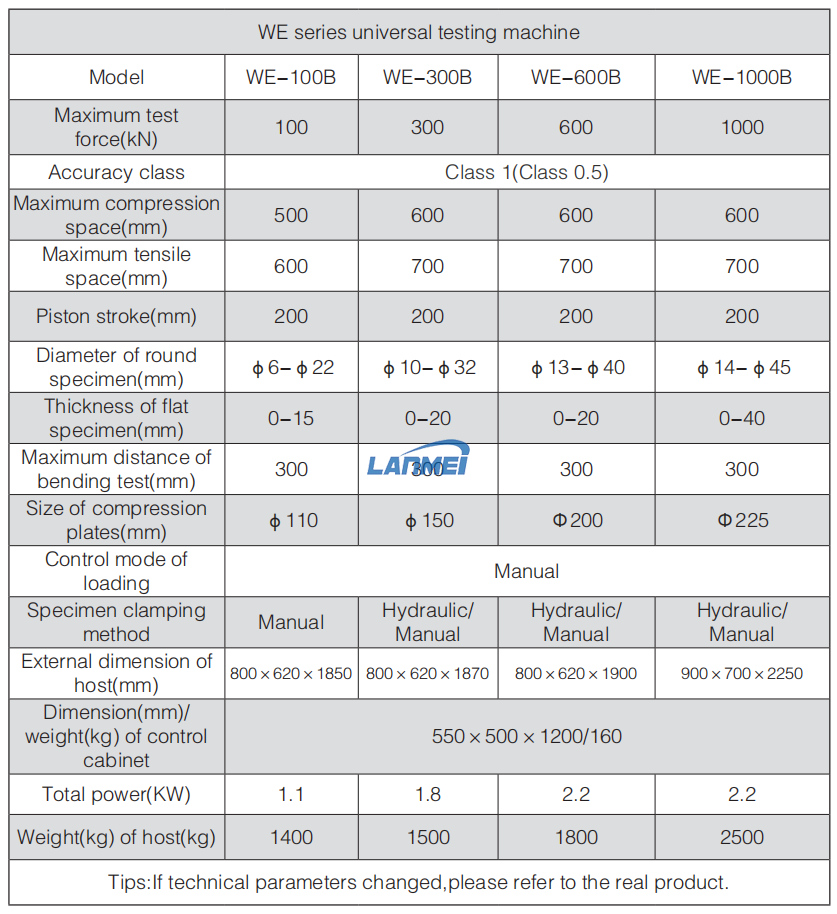

WAW series electro-hydraulic servo universal test machine e ipapisitse le GB/T16826-2008 "electro-hydraulic servo universal test machine," JJG1063- 2010"electro-hydraulic servo universal test machine," GB/T228.1-2010 "lisebelisoa tsa tšepe tsa tšepe" - mokhoa oa ho etsa liteko ka mocheso oa kamore".Ke mochini o mocha oa tlhahlobo ea lisebelisoa o ntlafalitsoeng le ho etsoa ho latela seo.Letoto lena la mochini oa liteko o na le hydraulic, o sebelisa theknoloji ea ho laola servo ea electro-hydraulic servo bakeng sa liteko tsa tensile, tlhahlobo ea compress, tlhahlobo ea bend, tlhahlobo ea ho kuta ea lisebelisoa tsa tšepe le tse seng tsa tšepe, e bonts'a mefuta e fapaneng ea li-curve, ho kenyeletsoa khatello ea maikutlo, deformation, displacement. le mekhoa e meng e koetsoeng ea loop control, e ka fetoloa ntle ho mabaka tekong.E tlaleha le ho boloka data ka bo eona.E kopana le GB, ISO, ASTM, DIN, JIS le litekanyetso tse ling.

Likarolo tsa mochini oa tlhahlobo oa bokahohle oa WAW electro-hydraulic servo (mofuta oa B):

1.Tlhahlobo e amohela mokhoa oa ho laola othomathike oa microcomputer, o nang le ts'ebetso ea sekhahla sa khatello ea maikutlo, sekhahla sa khatello, ho boloka khatello ea maikutlo le tlhokomelo ea khatello;

2.Adopt high-precision hub-and-spoke sensor ho lekanya matla;

3.Host e amohelang likholomo tse 'nè le li-screw tse peli tsa tlhahlobo ea sebaka sa sebaka

4.Buisana le PC ka sehokelo sa puisano sa Ethernet sa lebelo le holimo;

5.Laola lintlha tsa tlhahlobo ka database e tloaelehileng;

6.Matla a phahameng, boima bo phahameng le letlooa le letle la tšireletso bakeng sa tšireletso ea tšireletso.

Ts'ebetso ea pele le ts'ebetso

Ka mor'a ho qeta ho kenya motlakase, bulela matla a lisebelisoa, bulela lisebelisoa. Sebelisa karolo ea taolo holim'a khabinete ea taolo kapa lebokose la taolo, ho phahamisa girder e bohareng sebaka se selelele (haeba sefate se oela, o lokela ho emisa hang-hang ts'ebetso, lokisa tatellano ea karolo ea matla), ebe ho latela bukana, sebelisa lisebelisoa tse se nang moroalo, nakong ea ho phahama ha tafole ea ho sebetsa (e ke ke ea feta sekhahla se phahameng), ka kopo hlokomela hore na ho na le ketsahalo e sa tloaelehang, haeba e le lethal dose, o lokela ho hlakola le ho emisa ho hlahloba, ho lokisa bothata;haeba ho se joalo, ho laolla ho fihlela piston e theohela sebakeng se tloaelehileng, taelo e fela.

5.Mokhoa oa ts'ebetso

Mokhoa oa ts'ebetso oa tlhahlobo ea rebar

1.Etsa motlakase, etsa bonnete ba hore konopo ea ho emisa ha ts'ohanyetso ke pop-up, bulela controller holim'a phanele.

2.Ho latela diteng tsa teko le ditlhoko, kgetha le ho kenya clamp e tsamaelanang ya boholo.Mefuta ea boholo ba clamp e khethiloeng e tlameha ho kenyelletsa boholo ba mohlala.Ho lokela ho hlokomeloa hore tataiso ea ho kenya clamp e lokela ho

e tsamaellane le sesupo se ho clamp.

3. Bulela komporo, kena ka har'a software ea "TESTMASTER" 'me u kenye sistimi ea taolo, lokisa maemo a tlhahlobo ho latela litlhoko tsa tlhahlobo (mokhoa o sebelisoang oa taolo o bonts'itsoe ho "test machine software manual").

4.Bula terata, tobetsa konopo ea "mohlahare" holim'a phanele ea taolo kapa lebokoseng la taolo ea letsoho, bula mohlahare o ka tlase, beha mohlala ka har'a mohlahare ho latela litlhoko tsa maemo a tlhahlobo le mehlala e tsitsitseng mohlahareng, bula Mohlahare o ka holimo, tobetsa konopo ea "mid girder rising" ho phahamisa lesela le bohareng le ho lokisa boemo ba mohlala mohlahareng o ka holimo, ha boemo bo loketse ho koala mohlahare o ka holimo.

5.Koala terata, fokotsa boleng ba phalliso, qala ts'ebetso ea liteko (mokhoa o sebelisoang oa taolo o bonts'itsoe ho "test machine software manual").

6.Ka mor'a tlhahlobo, data e tlalehoa ka mokhoa o ikemetseng tsamaisong ea taolo, ebe e beha litaba tse hatisitsoeng ho software ea tsamaiso bakeng sa khatiso ea data (mokhoa oa ho beha mochine oa khatiso o bontšoa ho "test machine software manual").

7.Tlosa mohlala ho ea ka tlhoko ea teko, koala valve ea pelehi ebe o bulela valve ea ho khutlisa (mefuta ea WEW series) kapa tobetsa konopo ea "stop" ho software (WAW/WAWD series models), khutlisetsa thepa ho eona. boemo ba pele.

8.Tlohela software, koala pompo, koala molaoli le matla a maholo, Hlakola le ho hloekisa masala holim'a worktable, screw le snap-gauge ka nako ho qoba ho ama likarolo tsa phetisetso ea thepa.

6.Tlhokomelo ea letsatsi le letsatsi

Molao-motheo oa tlhokomelo

1.Nako le nako pele o qala mochine ka kopo, hlahloba hore na ho na le ho tsoa ha oli (likarolo tse khethehileng tse kang: pipeline, valve e 'ngoe le e' ngoe ea taolo, tanka ea oli), hore na bolt e tiisitsoe, hore na motlakase o tiile;hlahloba kamehla, boloka botšepehi ba likarolo tsa eona.

2.Ha u qeta teko e 'ngoe le e 'ngoe piston e lokela ho theoleloa boemong bo tlaase ka ho fetisisa, le masalla a hloekileng ka nako, worktable bakeng sa phekolo ea anti rust.

3.Ts'ebetso ka mor'a nako e itseng, u lokela ho ba le tlhahlobo e hlokahalang le tlhokomelo ka mochine oa teko: hloekisa masala a kang litšepe le mafome holim'a sebaka se thellang sa clamp le girder;hlahloba ho tiea ha ketane halofo ka 'ngoe ea selemo;tlotsa likarolo tse thellang khafetsa, penta likarolo tse mafome habonolo ka oli e thibelang mafome, lula u hloekile ebile u thibela mafome.

4.Thibela ho tloha mocheso o phahameng, ho koloba haholo, lerōle, mokhoa o senyang, sesebelisoa sa khoholeho ea metsi.

5. Kenya sebaka sa oli ea hydraulic selemo le selemo kapa ka mor'a lihora tsa 2000 mosebetsi.

6.Se ke oa kenya software e ngoe komporong, molemong oa ho qoba ho etsa hore software ea tsamaiso ea liteko e sebetse ka mokhoa o sa tloaelehang;thibela komporo ho tsoa tšoaetsong ea vaerase.

7.Pele u qala mochine o tlameha ho hlahloba hore na terata e kopanyang pakeng tsa k'homphieutha le moeti le sesebelisoa sa plug ea matla se nepahetse kapa se lokoloha, u ka qala ka mor'a ho netefatsa se nepahetseng.

8.Nako efe kapa efe ha e khone ho chesa mohala oa motlakase le mohala oa pontšo, ho seng joalo ho bonolo ho senya ntho ea taolo.

9.Nakong ea teko, ka kopo u se ke ua hatella konopo ea "control cabinet panel", lebokose la ts'ebetso le software ea teko.U se ke ua phahama kapa ua oa girder nakong ea teko.U se ke ua kenya letsoho la hao sebakeng sa teko nakong ea tlhahlobo.

10.Nakong ea teko, u se ke ua ama lisebelisoa le mefuta eohle ea li-link, e le hore u se ke ua ama ho nepahala ha data.

11.Hangata hlahloba phetoho ea boemo ba tanka ea oli.

12.Sheba hore na mohala o hokahanyang molaoli o amana hantle kamehla, haeba o hlephile, o lokela ho tlamisoa ka nako.

13.Ka mor'a tlhahlobo haeba thepa e sa sebelisoe nako e telele, ka kopo koala matla a maholo, 'me ha u ntse u emisa lisebelisoa, u sebelise lisebelisoa bakeng sa ho se be le mojaro kamehla, e le ho netefatsa ha thepa e sebelisoa. hape, li-index tsa allperformance li tloaelehile.

Litlhahiso tse khethehileng:

1.Ke sesebelisoa sa ho lekanya ka nepo, e lokela ho ba batho ba maemong a tsitsitseng bakeng sa mochini.batho ba se nang koetliso ba thibetsoe ka thata ho sebelisa mochine. konopo e khubelu ea ho emisa ts'ohanyetso ebe o tima motlakase.

2.Fasten linate holim'a sekoti sa mofuta oa T sa ho kobeha bering pele ho teko ea ho khumama, ho seng joalo e tla senya sekoti se kobehang.

3.Pele ho teko e otlollang, ka kopo etsa bonnete ba hore ha ho letho sebakeng se hatelitsoeng.Ho thibetsoe ho etsa tlhahlobo ea ho otlolla ka sesebelisoa se kobehang, ho seng joalo ho tla baka tšenyo e kholo ho sesebelisoa kapa kotsi ea motho ea lemetseng.

4.Ha u lokisa sebaka sa ho khumama ka girder u tlameha ho ela hloko haholo sebaka sa mohlala le rolara ea khatello, ho thibetsoe ka thata ho qobella mohlala ka ho toba ka ho phahama kapa ho oa ha girder, ho seng joalo e tla baka tšenyo e khōlō ho thepa. kapa kotsi ya kotsi ya motho.

5.Ha thepa e hloka ho falla kapa ho senyeha, ka kopo tšoaea pipeline le potoloho ea motlakase esale pele, e le hore e ka kopanngoa hantle ha e kenngoa hape;ha thepa e hloka ho phahamisoa, ka kopo, oela girder ho ea sebakeng se tlase kapa u behe lehong le tloaelehileng lipakeng tsa girder le tafole ea ho sebetsa (ke hore, ha hoa tlameha ho ba le tumello lipakeng tsa girder le tafole ea ho sebetsa pele u phahamisa moamoheli), ho seng joalo piston e bonolo. ho tsoa ho cylinder, ho lebisa ts'ebelisong e sa tloaelehang.

-

E-mail

-

Wechat

Wechat

-

Whatsapp

whatsapp

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur