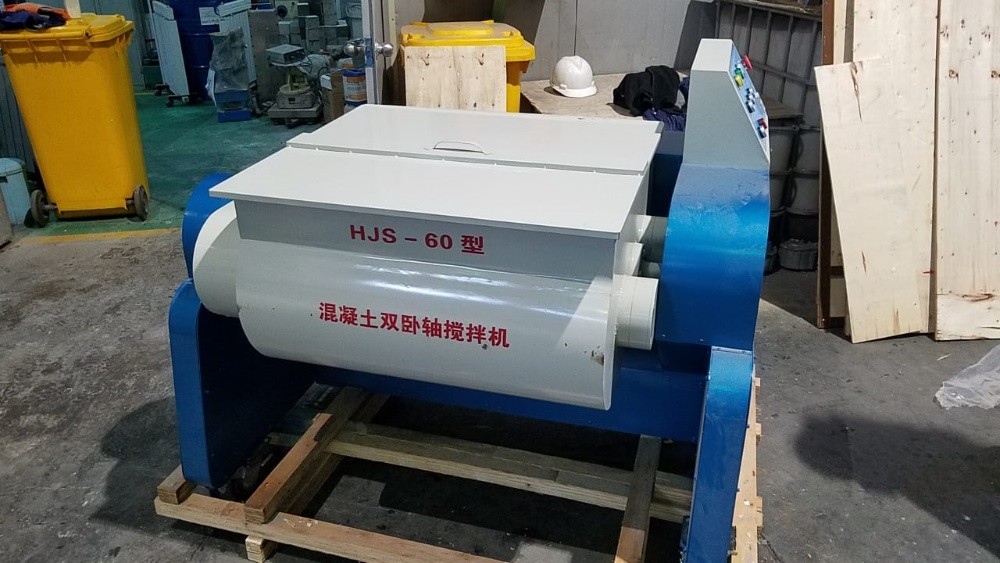

Ho qobella mofuta o mong le o mong oa konkreiti oa laboratoring oa laboratoring oa konkreite "oa konkreite" o ka etsa kopo e tloaelehileng le likotlo tse phahameng tsa ho kopanya, esita le ho kopanya, chelete ea ho lula e le nyane, tiiso e ntle, phofo e nyane, e bonolo, ke lisebelisoa tse matla tsa laboratori ho sebelisa konkreiti ea kopanya.

Motsoako ona oa konkreiti o sebelisoa bakeng sa ts'ebeliso ea laboratori, ke motsoako o qobelloang oa mofuta o nang le moqomo o habeli.

1.connect ea motlakase e facket ea motlakase.

2.SWHCHITECHTITECHH INAR Switch ', ho leka ho lekanya ha mekhahlelo. Haeba liphoso tsa karolo ea Mokhalo, tsa mantlha tsa mantlha li tla uema le lebone le bonesa. Ka nako ena ha ea lokela ho fokotsa matla a ho qala le ho lokisa lithapo tse peli tsa mollo.

3.Check konopo ea "boemo ba tšohanyetso" e bulehile, ka kopo e reset haeba e butsoe

Hlahloba boitsebiso ba ho kopanya ka kamoreng e kopanyang, koahela sekoaelo se kaholimo.

5.set ea ho kopanya (kamehla ea fektheri ke motsotso o le mong).

6.Press ea 6.Press "e kopanyang ', Motor o qala ho sebetsa, ho emisa ho kopanya.

Bapala sekoaelo ka mor'a ho kopanya ho emisitse, beha lebokose la lintho tse ka tlase, 'me le sutume ka mabili a bokahohleng.

8. Phula konopo ea "ho theolletso ',' Sesupo sa 'Matšoao se ka nko e tšoanang.

1. Tlanya konopo ea 'Mixing', e kopanyang ea koloi e kopanyang, hlakola lisebelisoa tse hloekileng (li hloka ka metsotsoana e 10).

Lekola konopo ea "STOR", koloi e kopanyang e emisa ho sebetsa.

11.Peress The 'Reset'button, ho lahla koloi ho matha ka mokhoa o ts'oanang, likoloi tse kopanyang tse 180 li tlole ka nako e le' ngoe.

2clean kamore ea ho boloka chelete ea ho lokisa ho kopanya nako e tlang.

TLHOKOMELISO:

(2) Ha o kenya samente, lehlabathe le lehloeo, ha lea thibeloa ho lula le lipekere, terata ea tšepe e thata, e le hore e se ke ea senya mochini.

Sebopeho sa Tlhabo ea Mahlale: Shaft e habeli

Bophahamo ba lentsoe: 60l

Mehala ea motor ea koloi: 3.0kw

Ho laolla motlakase oa koloi: 0,75kw

Lisebelisoa tse kopanyang: 16mn steel

Lisebelisoa tse kopanyang vane: 16mn steel

Nako le bophara bo pakeng tsa lerako le lerako: 1mm

Trum lebone la Drum: 10mm

Botenya ba vane: 12mm

Boholo bo boholo: 1100 × 900 × 1050

Boima ba 'mele: Approck 700kg

Ts'ebetso le ts'ebeliso

1. Hokela plug ea motlakase ka har'a socket ea motlakase.

2. Fetolela switch switch ', ho leka ho lekanya ha mekhahlelo. Haeba liphoso tsa karolo ea Mokhalo, tsa mantlha tsa mantlha li tla uema le lebone le bonesa. Ka nako ena ha ea lokela ho fokotsa matla a ho qala le ho lokisa lithapo tse peli tsa mollo.

3. Lekola hore na konopo ea Boemo ba tšohanyetso "e bulehile, ka kopo e reset haeba e bulehile (e potoloha ho latela tataiso e bontšitsoeng ke motsu).

4. Beha thepa ka kamoreng e kopanyang, e koahela sekoahelo se kaholimo.

5. Behela nako ea ho kopanya (kamehla ea fektheri e le motsotso o le mong).

6. Tobetsa konopo ', koloi e kopanya', e qala ho sebetsa, ho emisa ho kopanya, ho ka tobetsa konopo ea 'Stock.

7. Lahla sekoaelo ka mor'a ho kopanya ho emisitse, beha lebokose la lintho tse ka tlase, 'me le sutume ka mabili a bokahohleng.

8. Tobetsa konopo ea 'ho u butlisa'

9. Tobetsa konopo ea 'Mixing', motor ea kopanyang, o ile a hlakola lingoliloeng tse hloekileng (li hloka metsotso e 10).

10. Tobetsa konopo ea "STOR", koloi e kopanya motsoa e emisa ho sebetsa.

11. Tobetsa "Reset'Button, ho lahla koloi ho matha ka mokhoa o ts'oanang, masene a kopanya ka nako e tšoanang a tlohele ka nako e le 'ngoe.

Hlatsoa kamore le lijaki hore li itokisetse ho kopanya nako e tlang.

TLHOKOMELISO:

(2) Ha o kenya samente, lehlabathe le lehloeo, ha lea thibeloa ho lula le lipekere, terata ea tšepe e thata, e le hore e se ke ea senya mochini.

Nako ea poso: Mots'eanong-06-2023